Anchor Bolting & Huck Bolting

We make, export, and sell a wide range of Anchor Bolting & Huck Bolting, which are often used to hold two surfaces together.

Showing 1–12 of 46 results

-

-

Rivets (40)

-

Avdel Avdelmate

Fast Facts:

- Non-structural breakstem rivet.

- Rivet stem retained in tubular component to avoid loose stems.

- Blind hole, one-sided installation capability.

- Extra-wide grip range from 15.8 mm to 98.4 mm (5/8″ to 3-7/8″).

- Large bearing area against both sides of the application.

- Spreads the tail bearing load/clamp load on the rear sheet to prevent damage.

- Clamps tightly and securely without crushing parent material.

- Excellent hole fill via radially expanded rivet body for a strong and vibration-resistant joint.

- Low profile headform on both sides of the application for a neat appearance.

- Can be used to fasten metal to metal, plastic to plastic, metal to plastic, metal rear sheet, and various composite materials.

- Breakstem fasteners can be customized to meet unique assembly requirements.

Specifications:

- Sizes: 4.8 mm and 6.4 mm (3/16″ and 1/4″)

- Materials: Aluminum alloy and steel

- Headforms: Dome

AVDELMATE® – SERIES Material Headform Series

Steel Dome Avdelmate® SSLMS Aluminium Alloy Dome Avdelmate® BALMS Body: Aluminium

Mandrel: Steel

Tube: AluminiumDome Avdelmate® BSLMS Details can be found in the Breakstem Systems Catalog available in our Document Library.

-

Avdel Avex

Fast Facts:

- Non-structural breakstem rivet.

- Retained stem.

- Blind hole, one-sided installation capability.

- Multi-grip capability.

- Good hole fill.

- Provides a large blind side bearing area against the rear sheet.

- Wide choice of installation tools.

- One fastener can be used to replace several standard grip fasteners.

- Accommodates wide variations in material thickness.

- Reduced fastener inventory and simpler stock control.

- Spreads the tail bearing load/clamp on the rear sheet.

- Ideal for use in thin sheet materials.

- Compensates for irregular, oversized, slotted, or misaligned holes.

- Can stop sheet movement in non-standard holes.

- Provides strong, vibration-resistant joints.

- No damage, electrical problems, or rattling due to loose stems.

- Breakstem fasteners can be customized to meet unique assembly requirements.

Specifications:

- Sizes: 3.0mm to 6.4mm (1/4″)

- Materials: Aluminum alloy with steel or stainless steel stems

- Headforms: Dome, countersunk, and large flange

-

Avdel Avibulb

Fast Facts:

- Non-structural breakstem rivet.

- Retained stem.

- Blind hole, one-sided installation capability.

- High shear and tensile strength.

- Good hole fill.

- Provides a large blind side bearing area against the rear sheet.

- Ideal for applications requiring elevated temperatures.

- Spreads the tail bearing load/clamp on the rear sheet.

- Ideal for use in thin sheet materials.

- Compensates for irregular, oversized, slotted, or misaligned holes.

- Can stop sheet movement in non-standard holes.

- Provides strong, vibration resistant joints.

- No damage, electrical problems, or rattling due to loose stems.

- Breakstem fasteners can be customized to meet unique assembly requirements.

Specifications:

- Sizes: 3.2mm (1/8″) to 6.0mm

- Material: Steel, zinc & clear passivated

- Headform: Dome

-

Avdel Avibulb XT

Fast Facts:

- Structural breakstem rivet.

- Reliable stem retention.

- Blind hole, one-sided installation capability.

- High shear and tensile strength.

- Multi-grip capability.

- High residual clamp load.

- Resists vibration and joint slippage.

- Good blind side footprint and bulb formation.

- Spreads the tail bearing load/clamp on the rear sheet.

- Suitable in softer materials.

- Underhead recess accommodates burrs around holes and spreads load evenly on top sheet.

- Avdel® patent protected.

- Breakstem fasteners can be customized to meet unique assembly requirements.

Specifications:

- Size: 6.4mm (1/4”) diameter

- Material: Steel, zinc & clear passivated

- Headform: Dome

-

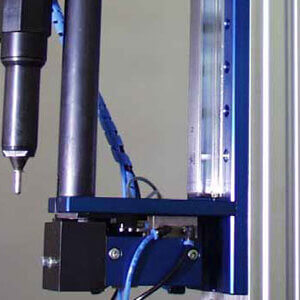

Avdel Avimat Automated Assembly System

Fast Facts:

- Compact, lightweight placing head can be mounted separately and work in any position.

- Modular design of blow feed unit and PLC control cabinet.

- Modular component design allows for quick and simple integration into assembly lines.

- Can work as a standalone unit.

- Integral processing diagnostics at all stages with clear and simple PLC displays

- Continuous fastener feed with average cycle time of approximately 5 seconds.

- Ideal for high-volume production lines.

-

Avdel Avinox

Fast Facts:

- Non-structural breakstem rivet.

- Retained stem.

- Blind hole, one-sided installation capability.

- High corrosion resistance.

- High shear and tensile strength.

- Good hole fill.

- Provides a large blind side bearing area against the rear sheet.

- Ideal for applications requiring elevated temperatures.

- Spreads the tail bearing load/clamp load on the rear sheet.

- Ideal for use in thin sheet materials.

- Compensates for irregular, oversized, slotted, or misaligned holes.

- Can stop movement in non-standard holes.

- Provides strong, vibration-resistant joints.

- Breakstem fasteners can be customized to meet unique assembly requirements.

Specifications:

- Sizes: 3.2mm to 4.8mm (1/8″ to 3/16″)

- Material: Stainless steel A2 and A4/316 Grade

- Headform: Dome

AVINOX® – SERIES Material Headform Series

Stainless Steel A2 Dome Avinox® BE61 Stainless Steel A4 Dome Avinox® BE16 Details can be found in the Breakstem Systems Catalog available in our Document Library.

-

Avdel Avlug

Fast Facts:

- Rolled/knurled shank ensures secure placement in the PCB.

- Suitable for wire wrapping or a test point for CRO tubes.

- Assembly applications include terminal posts and wire wrap.

Specifications:

- Sizes: 1.6mm, 2.4mm and 3.2mm (1/16”, 3/32″ and 1/8”)

- Materials: Electro tin-plated* brass (WEEE & RoHS compliant)

- Headforms: Dome

AVLUG® – SERIES Material Headform Series

Electro tin-plated* brass Dome Avlug® 1107 * Avdel® recommends tin-plated Avlug® parts are installed within nine months from the date they were produced.

Surface finish options

If you are looking for other surface finish options than shown in the above datasheets please download our. -

Avdel Avsert

Fast Facts:

- Blind hole, one-sided installation capability.

- Internally threaded bore takes a threaded part e.g. D-subminiature connectors.

- Available in many stand-off heights to accommodate a wide variety of components.

- Can be used for board thicknesses of 0.8-2.0 mm (short spigot) or 0.8-2.4 mm max (long spigot).

- Suitable as a female mating bush for D-subminiature connectors.

- Available as a customized design to meet your unique assembly requirements.

- Popular assembly applications include aluminum geartrays and extrusions, d-connectors, PCBs, and telecommunications equipment.

Specifications:

- Sizes: M2.5 X 0.45 and M3 X 0.5 threads

- Material: Tin-plated* brass

AVSERT® – SERIES Material Version Series Tin-plated* brass short spigot Avsert® 1117 Tin-plated* brass long spigot Avsert® 1118 * Avdel® recommends tin-plated Avsert® parts are installed within 24 months from the date they were produced.

-

Avdel Avtronic

Fast Facts:

- Blind hole, one-sided installation capability.

- Annular grooves on the body expand radially during installation.

- Provides a vibration-resistant joint, increased pull-out resistance, and good residual clamp.

- Available options accommodate most combinations of connector and PC board thickness.

- Available as a customized design to meet your unique assembly requirements.

Specifications:

- Sizes: 2.5mm and 2.8mm

- Materials: Electro tin plated* brass and aluminum alloy (WEEE & RoHS compliant)

- Headforms: Dome

AVTRONIC® – SERIES Material Headform Series

Aluminum alloy Dome Avtronic® 1189

Electro tin-plated* brass Dome Avtronic® 1188 * Avdel® recommends tin-plated Avtronic® fasteners are installed within nine months from the date they were produced.

-

Avdel Briv

Fast Facts:

- Bulbed tail and foreshortening of the fastener during installation ensures high clamp.

- Bulbed tail and large headform provide a large bearing area for soft materials.

- Tapered tail for ease of hole entry.

- Expands radially during installation to ensure maximum hole fill.

- Lower in-place costs than welding or nail rivets.

- Placed using a unique repetition mandrel system for high-speed assembly.

- Can be bowl fed for larger volume applications using automated equipment.

- Available as a customized design to meet your unique assembly requirements.

- Popular assembly applications include automotive, electronic components, sheet metal, electrical engineering, domestic appliances, furniture, and general light fabrication.

Specifications:

- Sizes: 2.4mm (3/32″) to 6.0mm

- Materials: Aluminum alloy, steel, stainless steel, brass, and tin-plated brass*

- Headforms: Dome/mushroom, countersunk

-

Avdel Bulbex

Fast Facts:

- Non-structural breakstem rivet.

- Retained stem.

- Blind hole, one-sided installation capability.

- Multi-grip capability.

- Split tail formation provides a very large blind side bearing area against the rear sheet.

- Wide choice of installation tools.

- One fastener can often be used to replace several standard grip fasteners.

- Accommodates wide variations in material thickness.

- Reduced fastener inventory and simpler stock control.

- Spreads the tail bearing load/clamp load on the rear sheet.

- No damage, electrical problems, or rattling due to loose stems.

- Breakstem fasteners can be customized to meet unique assembly requirements.

Specifications:

- Sizes: 4.0mm and 4.8mm (5/32″ and 3/16″)

- Material: Aluminium alloy

- Headform: Dome, large flange

-

Avdel Chobert

Fast Facts:

- Internally tapered bore ensures consistent light clamp to reduce potential damage to soft or brittle materials.

- The light clamp makes it ideal for use as a pivot pin or hose tail.

- Expands radially during installation to ensure maximum hole fill.

- Lower in-place costs than welding or nail rivets.

- Placed using a unique repetition mandrel system for high-speed assembly.

- Can be bowl fed for larger volume applications using automated equipment.

- Available as a customized design to meet your unique assembly requirements.

- Popular assembly applications include automotive, electronic component, sheet metal, electrical engineering, injection molded components, switchgear, domestic appliance, and light fabrication.

Specifications:

- Sizes: 2.4mm to 6.4mm (3/32″ to ¼”)

- Materials: Aluminum alloy, steel, brass, nickel-plated brass, and tin-plated brass*

- Headform: Dome/mushroom and countersunk

CHOBERT® – SERIES Material Headform Series

Aluminum Alloy Dome

120° Countersunk

Low profileChobert® 1125/31/35/64

Chobert® 1124/32/36

Chobert® 1162Steel Dome

120° CountersunkChobert® 1121

Chobert® 1122Brass – electro tin plated*

– nickel plated

Dome

Countersunk

Dome

Countersunk

Dome

CountersunkChobert® 1141

Chobert® 1142

Chobert® 1143

Chobert® 1144

Chobert® 1147

Chobert® 1148* Avdel® recommends tin-plated Chobert® fasteners are installed within nine months from the date they were produced.