Hydraulic Tools And Systems

Some of the tools used for Hydraulic Tools And Systems are Bottle Jacks, Piston Cylinders Spring , Cylinders Spring and a portable pressure testing kit.

Showing 1–12 of 104 results

-

-

Clamping Tools (14)

-

Hydraulic Cylinder (27)

-

Hydraulic Jacks (5)

-

Hydraulic Presses (5)

-

Hydraulic Puller (20)

-

Hydraulic Pumps (23)

-

Hydraulic Spreader (1)

-

AHW Series Telescoping Bottle Jacks

Model Number Capacity Stroke Retracted Height min. Length of Screw Ext. Height w/screw Ext. No. pump Stroke to Ext. Piston 25.4 mm Saddle Dia. Base Size Beveled Base Pump Handle Length Handle effort at rated cap. Carry Handle Product Weight Ton (mm) (mm) (mm) mm mm mm (mm) (mm) Kg Kg A9006X 6 305 216 – 521 14 44 121×133 700 36 No 6.4 A9011X 11 262 200 68 530 25 41 160×165 700 40 No 8.8 A9013X 13 254 230 84 570 35 48 176×186 700 36 No 11.3 A9015X 15 181 170 70 419 32 52 143×194 600 43 No 12 -

Bottle Jacks (Abj Series)

Model Number Capacity Stroke Min. Height Max. Height Head Screw Weight Ton (mm) (mm) (mm) mm Kg ABJ-02 2 165 180 345 50 2.29 ABJ-03 9 173 191 364 60 2.79 ABJ-05 5 188 200 388 70 3.79 ABJ-08 8 192 200 392 70 5.69 ABJ-12L 12 163 177 340 76 6.58 ABJ-12 12 225 241 466 79 7.68 ABJ-20L 20 122 183 305 38 8.98 ABJ-20 20 158 271 429 – 11.97 ABJ-30 30 159 281 440 – 17.96 ABJ-50H 50 180 300 480 – 35.24 ABJ-100H 100 150 310 460 – 90.2 -

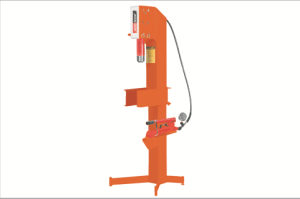

C-Frame Press

Capacity (ton) Type Cylinder Used Stroke (mm) Cylinder Model Model No. Speed Advance Pressing Type Pump Pump Model Weight (kg) 25 Single Acting 159 ARC-256 APM256C 3.3mm /stroke 0.8mm /stroke Hand P-109 108 -

CGG#N – Cylinders, Load Return With End Of Stroke Nut – High Tonnage

Feauters

These cylinders are particularly suitable for applications in which the load has to be supported for long periods. The lock nut can be screwed down onto the cylinder body to hold the load mechanically. This ensures that it’s absolutely safe to operate under load.

CGG cylinders have concentric grooves machined on the end of the rod to improve the load grip, models above 30 ton have lifting eyelets to facilitate their transport.

From 50 ton upwards, the cylinders are plunging type (P version) and have a system which prevents any possible over-stroke. The rod has a coloured zone which becomes visible 10 mm before the end of the piston stroke.

All models can operate with off-centred load up to 8% of their nominal capacity.OPERATIONAL AREAS

The ideal use for these cylinders is in the Construction Industry for example, bridge repairs and constructions and in the building and maintenance of heavy structural works. The anti-corrosion treatment applied to these cylinders makes them suitable for use in harsh and adverse environments.

OPTIONS:

– T version, cylinder with integrated tilt saddle.

– F version, cylinder with mounting holes for fixing purposes at the bottom.

– N version, (optional starting from 50 t) cylinders with end of stroke ring nut.This version is in compliance with ANSI B30.1.

– M version, cylinder with spring return.This version is available for N – version cylinders up to 150 tons (i.e., CMG50N100).

ACCESSORIES:

– ZTT tilt saddle reduces the effects of any possible off-centred load.

-

CGG#P – Cylinders, Load Return Without End Of Stroke Nut – High Tonnage

Feauters

These cylinders are particularly suitable for applications in which the load has to be supported for long periods. The lock nut can be screwed down onto the cylinder body to hold the load mechanically. This ensures that it’s absolutely safe to operate under load.

CGG cylinders have concentric grooves machined on the end of the rod to improve the load grip, models above 30 ton have lifting eyelets to facilitate their transport.

From 50 ton upwards, the cylinders are plunging type (P version) and have a system which prevents any possible over-stroke. The rod has a coloured zone which becomes visible 10 mm before the end of the piston stroke.

All models can operate with off-centred load up to 8% of their nominal capacity.OPERATIONAL AREAS

The ideal use for these cylinders is in the Construction Industry for example, bridge repairs and constructions and in the building and maintenance of heavy structural works. The anti-corrosion treatment applied to these cylinders makes them suitable for use in harsh and adverse environments.

OPTIONS:

– T version, cylinder with integrated tilt saddle.

– F version, cylinder with mounting holes for fixing purposes at the bottom.

– N version, (optional starting from 50 t) cylinders with end of stroke ring nut.This version is in compliance with ANSI B30.1.

– M version, cylinder with spring return.This version is available for N – version cylinders up to 150 tons (i.e., CMG50N100).

ACCESSORIES:

– ZTT tilt saddle reduces the effects of any possible off-centred load. -

CGR – Cilinders, Load Return With Safety Nut – Low Profile

Features

Pancake lock ring cylinders have a system which prevents any possible over-stroke. The rod on these cylinders has a coloured area which appears 10mm before the maximum stroke has been reached. This version does not conform to ANSI B30.1.

These cylinders are particularly suitable for applications in which the load has to be left in a raised position for long periods. The threaded safety nut, which blocks mechanically the cylinder boby, allows to operate in total safety under the load.

All cylinders are supplied with integrated tilt saddle and eyelets in order to ease their transport .

OPERATIONAL AREASCGR cylinders are suggested in the construction and maintenance of bridges, viaducts, building and industrial sites where the working space is limited. The protective nitriding treatment on these cylinders gives them excellent resistance to corrosion making them suitable for use in adverse environments.

STANDARD

– Integrated tilt saddle, reduces the effects of possible off-centred loads. -

CGS#D – Cylinders, Load Return Telescopic Double Stroke

Features

The hydraulic telescopic cylinders CGS are an efficient solution when you have very little space available below the load and when a long stroke is required. They can be manufactured with double stroke (D) or with triple stroke (T).

Given the high expansion only the 3% of maximum side load is allowed.

OPERATIONAL AREAS

This type of cylinder has various applications, especially in lifting of machineries but it’s considered very handy in areas with restricted space.

-

CGS#N – Cylinders, Load Return Standard – For High Tonnage

Features

CGS cylinders also have concentric grooves machined into the end of the rod to improve load grip, models above 30 tonne have lifting eyelets to facilitate their transport. From 50 ton upwards, the cylinders are plunging type (P version) and have a system which prevents any possible over-stroke. The rod has a coloured zone which becomes visible 10 mm before the end of the piston stroke.

All models can operate with off-centred load up to 8% of their nominal capacity.OPERATIONAL AREAS

These hydraulic cylinders are extremely solid and are recommended for the lifting, lowering and sustaining of a heavy load.

They are carried out specifically strong in order to be usefull in applications which require very heavy loads to be lifted.

The anti-corrosion treatment applied to these cylinders makes them suitable for use in harsh and adverse environments.OPTIONS:

– T version, cylinder with integrated tilt saddle.

– F version, cylinder with base mounting holes for fixing purposes.

– N version, (optional starting from 50 t) cylinders with end of stroke ring nut.This version is in compliance with ANSI B30.1.

ACCESSORIES :

– ZTT tilt saddle reduces the effects of any possible off-centred load.

-

CGS#P – Cylinders, Load Return Standard – For High Tonnage

Features

CGS cylinders also have concentric grooves machined into the end of the rod to improve load grip, models above 30 tonne have lifting eyelets to facilitate their transport. From 50 ton upwards, the cylinders are plunging type (P version) and have a system which prevents any possible over-stroke. The rod has a coloured zone which becomes visible 10 mm before the end of the piston stroke.

All models can operate with off-centred load up to 8% of their nominal capacity.OPERATIONAL AREAS

These hydraulic cylinders are extremely solid and are recommended for the lifting, lowering and sustaining of a heavy load.

They are carried out specifically strong in order to be usefull in applications which require very heavy loads to be lifted.

The anti-corrosion treatment applied to these cylinders makes them suitable for use in harsh and adverse environments.OPTIONS:

– T version, cylinder with integrated tilt saddle.

– F version, cylinder with base mounting holes for fixing purposes.

– N version, (optional starting from 50 t) cylinders with end of stroke ring nut.This version is in compliance with ANSI B30.1.

ACCESSORIES :

– ZTT tilt saddle reduces the effects of any possible off-centred load. -

CGS#T – Cylinders, Load Return Telescopic Triple Stroke

Features

The hydraulic telescopic cylinders CGS are an efficient solution when you have very little space available below the load and when a long stroke is required. They can be manufactured with double stroke (D) or with triple stroke (T).

Given the high expansion only the 3% of maximum side load is allowed.OPERATIONAL AREAS

This type of cylinder has various applications, especially in lifting of machineries but it’s considered very handy in areas with restricted space.

-

CMC – Extra Flat Cylinders – Spring Return

Features

The CMC range of cylinders have grooved end rods to improve the load grip, models over 20 tonne also have two threaded holes in the end rod to facilitate the screwing of the tilt saddle. All models have two holes which allows the cylinder to be bolted down onto a work surface; their flat sides also allow them to be used horizontally. Models over 5 tonne are fitted with a wiper seal and from 75 tonne upwards they are fitted with a removeable carrying handle. The CMC5N6 model is supplied with a K71F coupler (1/4” NPT connection).

OPERATIONAL AREAS

These extra compact lightweight cylinders are the ideal solution to operate in the narrowest working areas. They are used for the lifting of machineries, transformers and bridge sections while in the ship building industry can be used to raise engines into position and remove propellers.

ACCESSORIES:

– ZTT tilt saddle reduces the effects of any possible off-centred load.STANDARD:

-Tilt saddle mounting holes. -

CMF#L – Steel Hollow Piston Cylinders Spring Return

Features

All the CMF cylinder series are supplied with a smooth hollow saddle and the cylinder body, rod and bottom are threaded to facilitate the fixing and fitting of eventual accessories. The end of stroke nut has a wiper seal which prevents the penetration of dirt inside the cylinder. Cylinders are supplied with anti-corrosive treatment which is very effective to protect the central bore.

OPERATIONAL AREAS

These cylinders are recommended for tensioning and for the extractiong of pulleys, bushes and heat exchangers.They can also be used in both pulling and pushing operations by inserting either a bar or a cable through the hollow saddle. These cylinders are also supplied with the UE pullers

ACCESSORIES:

– ZTE threaded saddle Allows the fitting of threaded bars usually for extractors (UEC / UEG / UEZ / UET series).STANDARD:

– Smooth hollow saddle prevents any risk of any possible rod deformation.OPTIONS:

– L version, cylinders with aluminium body ( CMF###L### )