Description

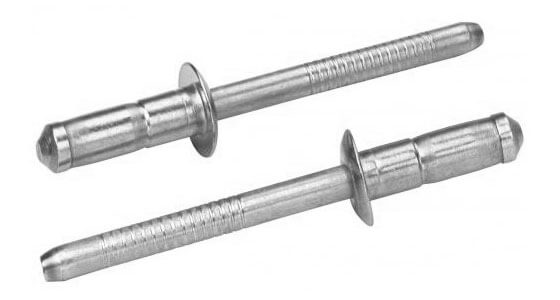

Briv speed fasteners feature a distinctive bulbed tail. The bulbed tail and foreshortening of the fastener during installation ensures a high joint clamp. The bulbed tail also works with the large headform to provide a large bearing area for soft materials.

With easy installation and lower in-place costs than welding or nail rivet techniques, this speed riveting system is extensively used for light fabrication. The Briv® is ideal for assembling many materials including metal, plastic, and aluminum alloy.

Placement occurs using a unique repetition mandrel system for high-speed assembly. The Briv® can also be bowl fed for larger volume applications using automated equipment.

Available in various finishes and options, the hot-tin-dipped brass option is recommended for soldering and good electrical continuity, while stainless steel is often used in applications subject to high temperatures or corrosion.