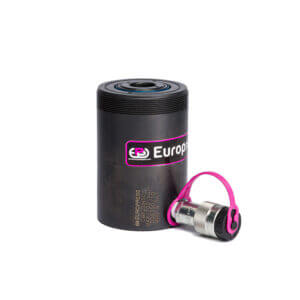

CGG#N – Cylinders, Load Return With End Of Stroke Nut – High Tonnage

Feauters

These cylinders are particularly suitable for applications in which the load has to be supported for long periods. The lock nut can be screwed down onto the cylinder body to hold the load mechanically. This ensures that it’s absolutely safe to operate under load.

CGG cylinders have concentric grooves machined on the end of the rod to improve the load grip, models above 30 ton have lifting eyelets to facilitate their transport.

From 50 ton upwards, the cylinders are plunging type (P version) and have a system which prevents any possible over-stroke. The rod has a coloured zone which becomes visible 10 mm before the end of the piston stroke.

All models can operate with off-centred load up to 8% of their nominal capacity.

OPERATIONAL AREAS

The ideal use for these cylinders is in the Construction Industry for example, bridge repairs and constructions and in the building and maintenance of heavy structural works. The anti-corrosion treatment applied to these cylinders makes them suitable for use in harsh and adverse environments.

OPTIONS:

– T version, cylinder with integrated tilt saddle.

– F version, cylinder with mounting holes for fixing purposes at the bottom.

– N version, (optional starting from 50 t) cylinders with end of stroke ring nut.

This version is in compliance with ANSI B30.1.

– M version, cylinder with spring return.

This version is available for N – version cylinders up to 150 tons (i.e., CMG50N100).

ACCESSORIES:

– ZTT tilt saddle reduces the effects of any possible off-centred load.