Description

The Chobert® speed fastener has a renowned history dating back to the 1930’s when it was used in the famous World War II Spitfire single-seat fighter planes. With easy installation and lower in-place costs than welding or nail rivet techniques, the Chobert® has remained a highly used speed fastener because it provides a consistent controlled clamp, and is ideal for soft or brittle materials.

Available in various finishes, including the hot-tin-dipped brass option for ease of soldering and good electrical continuity.

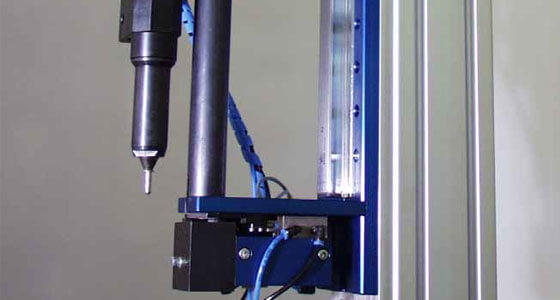

Placement occurs using a unique repetition mandrel system for high-speed assembly. The Chobert® can also be bowl fed for larger volume applications using automated equipment.