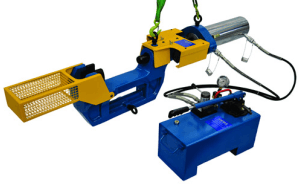

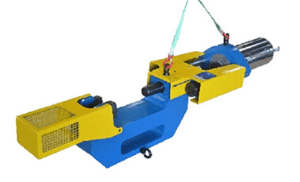

MM-PP -Modular Power Packs For Geotechnical Structural Tests Basic Version

Features

Many years of experience in the geotechnical field, in particular test piles, have enabled EUROPRESS to develop a complete product with special features answering the demands of this industry. The main features of the power pack, the core of the system are:

– Digital display that can be set up on the desired pressure values;

– Automatic pressure reactivation (also in case of structural yieldness) ;

– Hysteresis cycle system settings;

– Automatic or manual control ;

– Possibility to make test cycles

– by decreasing pressure ;

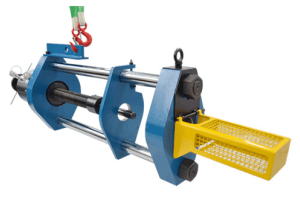

– It can be used with single and

double acting cylinders ;

– External pressure setting (50-700 bar range) ;

– Single or 3-phase electric motor ;

– Two stage pump 2,4/0,9 lt/min at 1400 rpm ;

– Manual 4 way 3 pos valve with pilot check ;

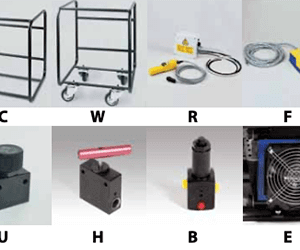

– 10, 20 or 40 litres tank ;

– Protective and transport cage ;

– 100 mm diameter analogic gauge.

OPERATIONAL AREAS

Non destructive tests on concrete structures, tests on construction materials and geotechnical experiments both on site and in laboratories.

Advanced version

ME-PP3 / MM-PP3

Features

These power pack have the same characteristics and ancillaries as the standard base version except for the 4 channel digital screen (1 pressure + 3 stroke positions). The operator has the possibility to keep under control in real time 4 different signals. These power packs can be connected directly to the PC thanks to an USB port. This function is useful to download the information of the tests accomplished.

ME-PPD / MM-PPD

Features

These power packs have the most advanced technology regarding geotechnical tests. They have the same characteristics and ancillaries as the standard versions but they have the freedom to check and custom all the functioning parameters and automatic work instructions; all these features make the –D version particularly suitable for the experts of this industry.

The main features are:

– HMI 10.1” touch screen display ;

– Real time 4 signal visualisation (1 pressure + 3 stroke positions) ;

– Free planning of lifting / lowering at different pressures ;

– Free planning of goal reaching / pressure maintaining ;

– → P(t) can be defined by the operator;

– Visualize final graphics ;

– Allows the direct connection to the PC through a USB port which is useful to download the information of the tests accomplished in CSV format (M.Excel) (pressure, movements, time, average movements and other parameters are available on request).