M#E10WR/4 -Hydraulic Power Packs For Big Capacity 700 Bar Torque Wrenches

Reservoir capacity: 10 l Delivery at 700 bar: 9,4-0,9 l/min Max pressure: 700 bar

Showing 1–12 of 23 results

Reservoir capacity: 10 l Delivery at 700 bar: 9,4-0,9 l/min Max pressure: 700 bar

Features

These very small single stage power packs have been specifically designed for small tools. They are designed to be specifically easy to use. Lightness and compactness are the main features of this unit.

All models are equipped with:

– Single-phase electric motor 230V – 50Hz – 0,25 Kw ;

– 3-way 2 position solenoid ;

– Relief Valve ;

– Plastic tank ;

– Plastic casing with integrated handle ;

– Oil level indicator ;

– Electric cable 2,5 m. length with Schuko plug ;

– 3 m. remote control.

Power packs with different voltage motors can be supplied upon request.

OPERATIONAL AREAS

Micro pumps are the ideal to control small tools like mini-presses, shears and nut-cutters.

They are compact and light (9 kg) therefore perfect in all applications where the pump has to be easy to carry.

OPTIONS :

– MC5# series on power units with 500 bar setting.

ACCESSORIES :

– ZMT carry belt.

Features

700 bar series

These two-stage Hydraulic Power Packs are particularly light and compact with excellent technical features. A large range of manual and electric controlled valves, allowes them to be used with single and double acting cylinders.

All models are equipped with either:

– Single phase electric motor 230 V – 50 Hz and 0,75 kW, 2800 rpm ;

– Two-stage piston pump ;

– Manual or electric 3 or 4-ways valves with or without pilot check ;

– Relief valve ;

– Plastic reservoir ;

– Plastic frame with carrying handle (excluding H version) ;

– Protective cage (only H version) dim. AxBxH – 400x250x420 mm ;

– Oil level gauge ;

– Electric cable 5 m ;

– Remote control 3 m (for electric valve).

1000 e 1500 bar series

Same characteristics of the 700 bar series a part from:

– Manual or electric 3 ways – 2 positions valve;

– Pressure regulation valve;

– G16 Gauge.

The following can be supplied if requested with voltage motor, air operated motor or with different capacity reservoir.

OPERATIONAL AREAS

700 bar Series: considering that are very easy to hadle they are ideal for medium sized tools. Particolarly suitable to be used with cutters, small presses, pipe bending machines and spreaders.

1000 bar Series: suitable to be used with tensioner mod. UTN e UTH.

1500 bar Series: suitable to be used with tensioner mod. UTV.

OPTIONS

700 bar Series:

– R version 3 m remote control usefull to active the motor. Available in power pack with manual series MDM##;

– H version power pack with high flow pump: 1° stage 6,0 l/min – 2° stage 0,6 l/min – motor 1,1 kW ;

– J version with pressure regulation valve.

1000 e 1500 bar Series:

– R version 3 m remote control usefull to operate the motor.

ACCESSORIES :

– RP52 gauge adaptor for G106 gauge. (700 bar versions only).

Features

Specifically designed for torque wrenches, these power packs combine maximum operating efficiency with a compact and lightweight design. Thanks to their compact dimensions and weight, they are easy to carry and are supplied with a handle or a protective frame.

All models are equipped with:

– 1/4” NPT male coupler on advance line and female on return line equipped with dust caps ;

– Two-stage piston pump ;

– Electric or pneumatic 4 ways 2 position valve ;

– Pressure regulating valve ;

– Pressure gauge ;

– Relief valve ;

– Plastic tank ;

– Plastic case with integrated handle (mod. MDWR) ;

– Protection housing (mod. MDWRH, MDWRP and MDWRHE) ;

– Oil level gauge ;

– 3 m. remote control ;

– 5 m. electric cable ;

– Heat exchanger (mod. MDWRHE).

4 different models are available:

– MDWR with 2,4/0,4 l/min pump and electric single phase 0,75 kW motor ;

– MDWRH with 6/0,6 l/min pump and electric single phase 1,1 kW motor ;

– MDWRP with 6/0,6 l/min pump and air 1,5 kW motor ;

– MDWRHE with 6/0,6 l/min pump and electric single phase 1,1 kW motor and heat exchanger.

OPERATIONAL AREAS

Ideal if combined with torque wrenches.

Features

These hydraulic power packs are designed to be modular in order to guarantee the complete interchangeability of the components. Thanks to this feature it is possible to order customized models. The top plate is used as a base on which to mount all the modular components (valves, and accessories). The valves are also mounted on a plate to allow the pressure adjustment on the return line.

The power packs are manufactured under high quality controls to ensure:

– Safety: The valves are set in our Factory and each component is in compliance with “2006/42/CE Machine Directive” and its following amendments. Furthermore they are CE marked in relation to the 2014/30 UE norms (electromagnetic compatible) and 2014/35 UE (low tension);

– Life: The components are all carefully chosen and this ensures excellent performance results, Power/weight ratio, and limited dimensional requirements and easy maintenance ;

– Environment: They are easy to use, the are quiet, reliable and guarantee the maximum performance.

The various models consist of:

– Motor , available in four versions: three-phase electric, single phase electric, petrol engine and air motor. Furthermore our electric motors are provided with magneto-thermal cut-out with 0 voltage disconnection, complete with 5 m power cord, CEE plug and Class IP54 protection ;

– Pump available in 12 versions from 0,45 to 10 l/min ;

– Relief valve adjustable from outside on all pumps and various types of manual, electric, air-operated and spring centred valves at your choice ;

– Tank from 5 to 50 litres ;

– Options to customize the power unit.

Check the chart on the next page for the correct interpretation of the hydraulic power units.

OPERATIONAL AREAS

They are essential for lifting and jacking systems with single and double acting cylinders and for all heavy duty or complex operations that cannot be performed with manual pumps.

Features

Many years of experience in the geotechnical field, in particular test piles, have enabled EUROPRESS to develop a complete product with special features answering the demands of this industry. The main features of the power pack, the core of the system are:

– Digital display that can be set up on the desired pressure values;

– Automatic pressure reactivation (also in case of structural yieldness) ;

– Hysteresis cycle system settings;

– Automatic or manual control ;

– Possibility to make test cycles

– by decreasing pressure ;

– It can be used with single and

double acting cylinders ;

– External pressure setting (50-700 bar range) ;

– Single or 3-phase electric motor ;

– Two stage pump 2,4/0,9 lt/min at 1400 rpm ;

– Manual 4 way 3 pos valve with pilot check ;

– 10, 20 or 40 litres tank ;

– Protective and transport cage ;

– 100 mm diameter analogic gauge.

OPERATIONAL AREAS

Non destructive tests on concrete structures, tests on construction materials and geotechnical experiments both on site and in laboratories.

Advanced version

ME-PP3 / MM-PP3

Features

These power pack have the same characteristics and ancillaries as the standard base version except for the 4 channel digital screen (1 pressure + 3 stroke positions). The operator has the possibility to keep under control in real time 4 different signals. These power packs can be connected directly to the PC thanks to an USB port. This function is useful to download the information of the tests accomplished.

ME-PPD / MM-PPD

Features

These power packs have the most advanced technology regarding geotechnical tests. They have the same characteristics and ancillaries as the standard versions but they have the freedom to check and custom all the functioning parameters and automatic work instructions; all these features make the –D version particularly suitable for the experts of this industry.

The main features are:

– HMI 10.1” touch screen display ;

– Real time 4 signal visualisation (1 pressure + 3 stroke positions) ;

– Free planning of lifting / lowering at different pressures ;

– Free planning of goal reaching / pressure maintaining ;

– → P(t) can be defined by the operator;

– Visualize final graphics ;

– Allows the direct connection to the PC through a USB port which is useful to download the information of the tests accomplished in CSV format (M.Excel) (pressure, movements, time, average movements and other parameters are available on request).

Features

Air- hydraulic pumps are extremely light and versatile. Tests results show how exceptionally reliable and suitable they are for the most difficult operations thanks to their unique design (series SA, MA, HA, TA, V,U made of plastic material outside and metal alloy inside). There are six multiplying factors: 19:1, 60:1, 122.1, 196:1, 278:1, 336:1, 484:1 for maximum oil pressure values respectively of 80, 350, 700, 1000, 1500, 2100, 3000 bar. All the pumps (version KA excluded) have a maximum pressure valve not adjustable from the outside. The outward pressure can be adjusted varying the inward air pressure.

The four basic versions are:

– MLP0 with P and T outlets, to be used with on-line valves ;

– MLP1 with Cetop 3 plate ;

– MLP2 with three-way valve (with control pedal) SA, MA, HA e TA, with manual acting valve for V, U and KAG models,for single acting cylinders ;

– MLP3 with three-way valve (with manual handwheel) for single acting cylinders ;

– MLP4 with four-way valve (with hand lever) four double acting cylinders.

Different ancillaries can be added to the basic version, this expands the pump’s functions, check the table on the next page.

OPERATIONAL AREAS

These air-hydraulic pumps are best if used in the rapid exchange of the equipments on machine tools (80 bar), in hydraulic clamping (80 and 350 bar), in the industrial sector (350 bar), for the lifting, the maintenance and in the automotive sector (700 bar) together with bolt tensioner cylinders and hydraulic nuts (1000 and 1500 bar), bearings press fitting, for laboratory and burst tests (1500 and 2100 e 3000 bar).

STANDARD ( on MLP21V, MLP21U and MLP23KAG )

– Cage ;

– Gauge ;

– Pressure reducer.

ACCESSORIES :

– ZML14 pressure reducer for air supply ;

– ZMB7 pressure booster adaptable to the MLP21# HA/MA/SA to multiply outgoing pressure (Ratio 4:1). Inlet 3/8˝ NPT, outlet 3/4˝ -16 UNF ;

– RP52 gauge adaptor for gauge type G106L (a part from models VA, KAG and U).

Features

These hydraulic power packs are designed to be modular in order to guarantee the complete interchangeability of the components. Thanks to this feature it is possible to order customized models. The top plate is used as a base on which to mount all the modular components (valves, and accessories). The valves are also mounted on a plate to allow the pressure adjustment on the return line.

The power packs are manufactured under high quality controls to ensure:

– Safety: The valves are set in our Factory and each component is in compliance with “2006/42/CE Machine Directive” and its following amendments. Furthermore they are CE marked in relation to the 2014/30 UE norms (electromagnetic compatible) and 2014/35 UE (low tension);

– Life: The components are all carefully chosen and this ensures excellent performance results, Power/weight ratio, and limited dimensional requirements and easy maintenance ;

– Environment: They are easy to use, the are quiet, reliable and guarantee the maximum performance.

The various models consist of:

– Motor , available in four versions: three-phase electric, single phase electric, petrol engine and air motor. Furthermore our electric motors are provided with magneto-thermal cut-out with 0 voltage disconnection, complete with 5 m power cord, CEE plug and Class IP54 protection ;

– Pump available in 12 versions from 0,45 to 10 l/min ;

– Relief valve adjustable from outside on all pumps and various types of manual, electric, air-operated and spring centred valves at your choice ;

– Tank from 5 to 50 litres ;

– Options to customize the power unit.

Check the chart on the next page for the correct interpretation of the hydraulic power units.

OPERATIONAL AREAS

They are essential for lifting and jacking systems with single and double acting cylinders and for all heavy duty or complex operations that cannot be performed with manual pumps.

Features

Many years of experience in the geotechnical field, in particular test piles, have enabled EUROPRESS to develop a complete product with special features answering the demands of this industry. The main features of the power pack, the core of the system are:

– Digital display that can be set up on the desired pressure values;

– Automatic pressure reactivation (also in case of structural yieldness) ;

– Hysteresis cycle system settings;

– Automatic or manual control ;

– Possibility to make test cycles

– by decreasing pressure ;

– It can be used with single and

double acting cylinders ;

– External pressure setting (50-700 bar range) ;

– Single or 3-phase electric motor ;

– Two stage pump 2,4/0,9 lt/min at 1400 rpm ;

– Manual 4 way 3 pos valve with pilot check ;

– 10, 20 or 40 litres tank ;

– Protective and transport cage ;

– 100 mm diameter analogic gauge.

OPERATIONAL AREAS

Non destructive tests on concrete structures, tests on construction materials and geotechnical experiments both on site and in laboratories.

Advanced version

ME-PP3 / MM-PP3

Features

These power pack have the same characteristics and ancillaries as the standard base version except for the 4 channel digital screen (1 pressure + 3 stroke positions). The operator has the possibility to keep under control in real time 4 different signals. These power packs can be connected directly to the PC thanks to an USB port. This function is useful to download the information of the tests accomplished.

ME-PPD / MM-PPD

Features

These power packs have the most advanced technology regarding geotechnical tests. They have the same characteristics and ancillaries as the standard versions but they have the freedom to check and custom all the functioning parameters and automatic work instructions; all these features make the –D version particularly suitable for the experts of this industry.

The main features are:

– HMI 10.1” touch screen display ;

– Real time 4 signal visualisation (1 pressure + 3 stroke positions) ;

– Free planning of lifting / lowering at different pressures ;

– Free planning of goal reaching / pressure maintaining ;

– → P(t) can be defined by the operator;

– Visualize final graphics ;

– Allows the direct connection to the PC through a USB port which is useful to download the information of the tests accomplished in CSV format (M.Excel) (pressure, movements, time, average movements and other parameters are available on request).

Caratteristiche Tecniche

These hydraulic power packs are designed to be modular in order to guarantee the complete interchangeability of the components. Thanks to this feature it is possible to order customized models. The top plate is used as a base on which to mount all the modular components (valves, and accessories). The valves are also mounted on a plate to allow the pressure adjustment on the return line.

The power packs are manufactured under high quality controls to ensure:

– Safety: The valves are set in our Factory and each component is in compliance with “2006/42/CE Machine Directive” and its following amendments. Furthermore they are CE marked in relation to the 2014/30 UE norms (electromagnetic compatible) and 2014/35 UE (low tension);

– Life: The components are all carefully chosen and this ensures excellent performance results, Power/weight ratio, and limited dimensional requirements and easy maintenance ;

– Environment: They are easy to use, the are quiet, reliable and guarantee the maximum performance.

The various models consist of:

– Motor , available in four versions: three-phase electric, single phase electric, petrol engine and air motor. Furthermore our electric motors are provided with magneto-thermal cut-out with 0 voltage disconnection, complete with 5 m power cord, CEE plug and Class IP54 protection ;

– Pump available in 12 versions from 0,45 to 10 l/min ;

– Relief valve adjustable from outside on all pumps and various types of manual, electric, air-operated and spring centred valves at your choice ;

– Tank from 5 to 50 litres ;

– Options to customize the power unit.

Check the chart on the next page for the correct interpretation of the hydraulic power units.

OPERATIONAL AREAS

They are essential for lifting and jacking systems with single and double acting cylinders and for all heavy duty or complex operations that cannot be performed with manual pumps.

Features

These hydraulic power packs are designed to be modular in order to guarantee the complete interchangeability of the components. Thanks to this feature it is possible to order customized models. The top plate is used as a base on which to mount all the modular components (valves, and accessories). The valves are also mounted on a plate to allow the pressure adjustment on the return line.

The power packs are manufactured under high quality controls to ensure:

– Safety: The valves are set in our Factory and each component is in compliance with “2006/42/CE Machine Directive” and its following amendments. Furthermore they are CE marked in relation to the 2014/30 UE norms (electromagnetic compatible) and 2014/35 UE (low tension);

– Life: The components are all carefully chosen and this ensures excellent performance results, Power/weight ratio, and limited dimensional requirements and easy maintenance ;

– Environment: They are easy to use, the are quiet, reliable and guarantee the maximum performance.

The various models consist of:

– Motor , available in four versions: three-phase electric, single phase electric, petrol engine and air motor. Furthermore our electric motors are provided with magneto-thermal cut-out with 0 voltage disconnection, complete with 5 m power cord, CEE plug and Class IP54 protection ;

– Pump available in 12 versions from 0,45 to 10 l/min ;

– Relief valve adjustable from outside on all pumps and various types of manual, electric, air-operated and spring centred valves at your choice ;

– Tank from 5 to 50 litres ;

– Options to customize the power unit.

Check the chart on the next page for the correct interpretation of the hydraulic power units.

OPERATIONAL AREAS

They are essential for lifting and jacking systems with single and double acting cylinders and for all heavy duty or complex operations that cannot be performed with manual pumps.

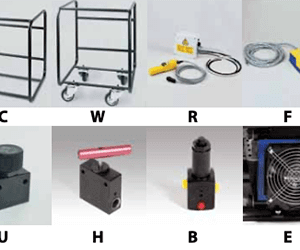

Caratteristiche Tecniche

– G – Glycerine filled pressure gaugeØ 100 with manual VMEW valve and Ø 63 with solenoids and with controlled check manual or counterbalance valves(digital gauge upon request) ;

– C – Protective housing (standard for MS power packs) ;

– W – Protective housing with 4 pivoting wheelS Ø 80×25 mm) ;

– N – Emergency button ;

– R – Manual activated remote control, 5 metres long;

– F – Pedal activated remote control, 5 metres long;

– P – Pressure sensor and pressure gauge ;

– L – Filter and pressure reducer for air motor models;

– U – Unidirectional flow regulator;

– H – Unidirectional flow regulator with fine regulation, mounting plate;

– E – Heat exchanger ;

– S – Filter on return line(not available for 5 l and 10 l tank power packs tank high).

CUSTOMIZED VERSIONS

– Z – Without hand wheel adjustable pressure valve ;

– Y – Without magneto-thermal switch For electric motor models.

ACCESSORIES

– ZMD## Rain proof cover kit for power packs.

– ZMK## Rain proof / dust proof polyester waterproof cover for power packs.

You cannot copy content of this page